Injection Molded Plastics Industry Information

Injection Molded Plastics

Injection molding is a manufacturing process for producing parts in which material is injected into a mold. The material for the desired piece is poured or pumped into a heated barrel, where it is mixed to a homogeneous consistency and then forced into the mold’s cavity, where it will cool down and harden until the finished piece has solidified in the shape of the mold.

Because of this, injection molding is best utilized by manufacturers who want to make large quantities of the same part. It is of particular value for manufacturers who desire very low tolerances in the parts that are produced, as the parts-per-million defect rate of injection molding manufacturing is extremely low.

Injection molding is used primarily to create parts that would be very difficult to make by hand. Because the molds that the plastics are poured into can take very intricate shapes, it allows manufacturers to produce pieces that are designed in extremely fine detail. The mold being used is designed in a 3D modeling software program, which ensures that the mechanical engineers who are designing the part have complete control over every dimension of the finished product.

Due to the low cost and efficiency with which the injection molding process operates, it is utilized in a wide range of industries such as automotive parts, musical instruments, furniture, and many more. Injection molding is used to produce goods that are used in almost every single aspect of our everyday lives.

Some examples of products that are produced by injection molding include: flutes, one-piece chairs, storage containers, wire spools, bottle caps, pocket combs, plastic cups, and many more.

Quick links to Injection Molded Plastics Information

- The History of Injection Molding

- Injection Molded Plastic Types

- Materials and Properties of the Injection Molding Process

- Injection Molding Process

- Important Design Elements to Consider for Injection Molding

- The Types of Equipment Used for the Injection Molding Process

- How to Choose the Right Molding Manufacturer

- Injection Molded Plastic Terms

The History of Injection Molding

- The Origins of Injection Molding

- The injection molding process was originally invented by John Wesley Hyatt and his brother Isaiah in 1872. Their original design was extremely crude compared to the current machines that are employed in the injection molding process. Their original machine functioned similarly to a large hypodermic needle, and utilized a plunger to push plastic through a heated barrel into a steel mold that had to be ground by hand.

- The original injection molding process was not capable of producing anything nearly as complex or as large of a scale as current machines can produce. Early uses for the process included buttons, combs, and collar stays.

- The Evolution of the Molding Process

- The industry progressed very slowly in the years immediately following 1872. In 1903, the industry would see further advances from German chemists Arthur Eichengrun and Theodore Becker, who would invent the first soluble forms of cellulose acetate in 1903. This advancement was important due to the fact that cellulose acetate is much less flammable than cellulose nitrate, which was what was previously used.

- These advances would lead to the cellulose acetate being made available in a powder form, which made it much easier to transport and distribute to manufacturers. In 1919, Arthur Eichengrun would go on to patent the injection molding process based on the first modern injection molding machine.

- The industry would see further rapid changes thanks to World War II, which created an overwhelming demand for mass-produced goods at extremely low prices. James Watson Hendry, an American inventor, built the first screw injection machine in 1946. This machine was vital due to the fact that it allowed a great deal of precision in regards to the rate of injection. This in turn affected the quality of the goods produced by reducing the overall rate of error.

- Another important aspect that the screw injection machine introduced into the process is that it allowed the raw material to be mixed prior to injection. This would prove to be extremely important as it allowed for colored and recycled plastic to be mixed with the molten plastic and mixed to a homogeneous consistency before being injected into the mold.

Injection Molded Plastic Types

- Custom Injection Molding

- An injection molding process in which the mold is not pre-made, but is formed specifically for the consumer’s application.

- Double-Shot Molding

- A two-step process in which either the color or the material is injected first. Upon the hardening of the material, a second color or material is injected into or around the first shape.

- Gas-Assist Injection Molding

- A process in which inert gas, such as nitrogen, is forced into the melt while it is entering the mold, packing the plastic into the cavities. Gas-assisted injection molding reduces cycle time, part weight, warpage and stress to the cooled parts, as well as minimizing other problems.

- Injection Blow Molding

- The process in which plastic is injected into a mold to form a plastic tube. The tube is then blown into a cavity mold to form a hollow part.

- Injection Molding

- A process by which plastics parts and products are formed.

- Injection Moulders

- The tools and die machines used to mold molten plastic.

- Injection Molded Cases

- Durable carrying cases made of plastic that are used to hold and transport delicate or valuable pieces of equipment and protect them from damage.

- Injection Molded Parts

- Simple parts that are made from the injection molding process. The injection molding process yields a number of different products that are utilized in a variety of applications.

- Insert Molding

- An injection molding process in which plastic gets injected into a cavity surrounding an insert piece just prior to molding. Plastic insert molding results in a single piece encapsulated by the plastic.

- Molded Plastic Pieces

- Parts that are formed by pouring heated plastic into molds. Plastic injection molding is a process by which plastic is heated into a malleable form and pressed into molds.

- Plastic Injection Mold Processes

- Used to fabricate parts with a range of complexities, from simple shapes to precision parts of geometric complexity.

- Plastic Molding

- One of the most common methods of part manufacturing.

- Push-Pull Molding

- A process that involves multiple layers with different orientations, providing more uniform properties to the parts than if they were molded from a single direction.

- Prototype Injection Molding

- A form of injection molding that is used to make short run batches, or single products used for prototype purposes.

- Rapid Injection Molding

- Primarily used in prototyping and the low-volume production of plastic parts since the production time is drastically shorter than conventional molding process.

- Reaction Injection Molding

- An economical option commonly used for larger, more complex polyurethane plastic and rigid foam parts produced in small quantities.

- Thermoplastic Injection Molding

- Most common method used to process thermoplastics, due to its ability to fabricate parts with a range of design variances, from simple shapes to high precision parts of geometric complexity.

Materials and Properties of the Injection Molding Process

- Materials Utilized In the Injection Molding Process

- A wide range of custom plastic materials can be used in this process, and will vary depending on what the desired finished good is intended to be used for. Since 1995, the number of custom plastics available for production have been increasing at a rate of 750 per year; prior to 1995 there were about 18,000 materials available when the trend started.

- Custom plastic injection molding materials usually fall into one of three groups: thermoplastics, thermosets, or elastomers. Mechanical and material engineers will usually weigh the pros and cons of each type of material in great detail before finally deciding on the best choice for the job. Different parameters such as material strength, chemical exposure, and intended life of the product are all taken into account.

- Some well-known examples of injection mold plastic that are typically used in the injection molding process include: nylon, polyethylene, polystyrene, epoxy, and phenolic.

- Injection molders are not limited by manufacturing capabilities when it comes to material choice, and are able to fabricate a wide range of product shapes and sizes. If a mold can be made for an object, plastic molding can be used to produce a product. Everything from car bumpers to intricate medical equipment can be made using the techniques of melting the appropriate material, forcing it into a pre-made cavity and allowing it to cool.

- The Properties of Materials Used In the Process

- As mentioned above, the types of molten plastic that can be used in the production process fall into one of three categories: thermoplastics, thermosets, or elastomers.

- Thermoplastics, such as polyethylene, tend to have a high molecular weight and polymer chains that associate through intermolecular forces. What this means from a practical point-of-view is that they can be easily heated up to form molten plastic without a large amount of heat, and once they have cooled they can easily be broken back into molten plastic again if the molding process needs to be repeated due to an error or defect. For this reason, their main advantage over the other plastic injection mold materials is cost efficiency.

- A thermoset is a type of polymer that forms an irreversible polymer network upon curing from a liquid state to a solid state. Because of this, thermosets cannot be reused once they have solidified from a liquid to a solid. However, this is actually the advantage to using thermosets, such as epoxy, over thermoplastics or elastomers, as this makes thermosets incredibly durable once they have taken their final form.

- An elastomer exists in a state called viscoelasticity, meaning that it is able to change shape more easily than most other solids, but still has considerable material strength. Rubber is the most commonly known example of an elastomer. The advantage that elastomers, such as nylon, have over the other two types of materials is that they tend to be extremely versatile in what they can be used for.

Injection Molding Process

The plastic injection molding process starts out with the material existing in pellet form. These pellets are then fed through a hopper into a hot barrel, inside of which is a reciprocating screw. As soon as the pellets pass into the barrel, the temperature increases and the viscosity of the pellets is increased, at which point dyes or other chemical agents can be added to change the final appearance and feel of the product.

From this point, the material passes out of the barrel through a check valve, and gathers at the front of the screw. The screw is designed so that it collects exactly as much material is needed to fill the mold design. The screw is then inserted into the plastic injection mold and reciprocates until the plastic injection molding is filled with molten plastic material. Most molds will allow air bubbles to escape to avoid damaging the final product. Cooling liquids are sometimes used around the mold chamber of the machine to extract heat from the plastic and speed up the cooling process, thus saving time in overall manufacturing. The entire process can take a matter of seconds or as many as a few minutes to get one complete plastic part.

At this point, the plastic injection molding is left to cool and the screw retracts to gather material for the next round. The cooling is aided by lines pumping water or other types of coolant along the wall thickness of the plastic molding. Finally, pins in the plastic molding engage to eject the finished project from the mold.

- How the Injection Molding Process Can Be Customized

- The process can be customized in a number of different ways. One of the more popular tooling options is to use robotic molding, which has a series of small robotic arms and sensors that inspect each plastic part for defects to further ensure a high degree of quality.

- Another custom tooling option is to alter the insert molding material being used. By switching from steel insert molding to resin insert molding, this can increase the flow speed of the injection molded plastic. This will ultimately result in more plastic part tonnage per hour, at the risk of more defects. It is highly recommended that this tooling change only be made to a production line only after a qualified engineer has approved it.

- Drawbacks of the Injection Molding Process

- The injection molding process is not without its shortcomings. If the manufacturer desires to produce anything other than a plastic part, then they will have to look to another production process such as die-casting.

- Another drawback to the injection molding process is that it has an extremely high cost to start up. Designing a mold for the injection molding process is an extremely expensive and time consuming task. However, once the process is complete and the entire injection molding production is up and running, it becomes extremely cost effective in the long run.

Important Design Elements to Consider for Injection Molding

One of the biggest design elements that is necessary to consider when designing a custom injection molding process is the wall thickness of the mold design. This is a crucial parameter since the molding process depends greatly on the mold cavity and the tolerances it is designed to. If the mold cavity is improperly designed, there will not be enough pressure for the material to properly transfer from the screw to fill up the entirety of the plastic molding.

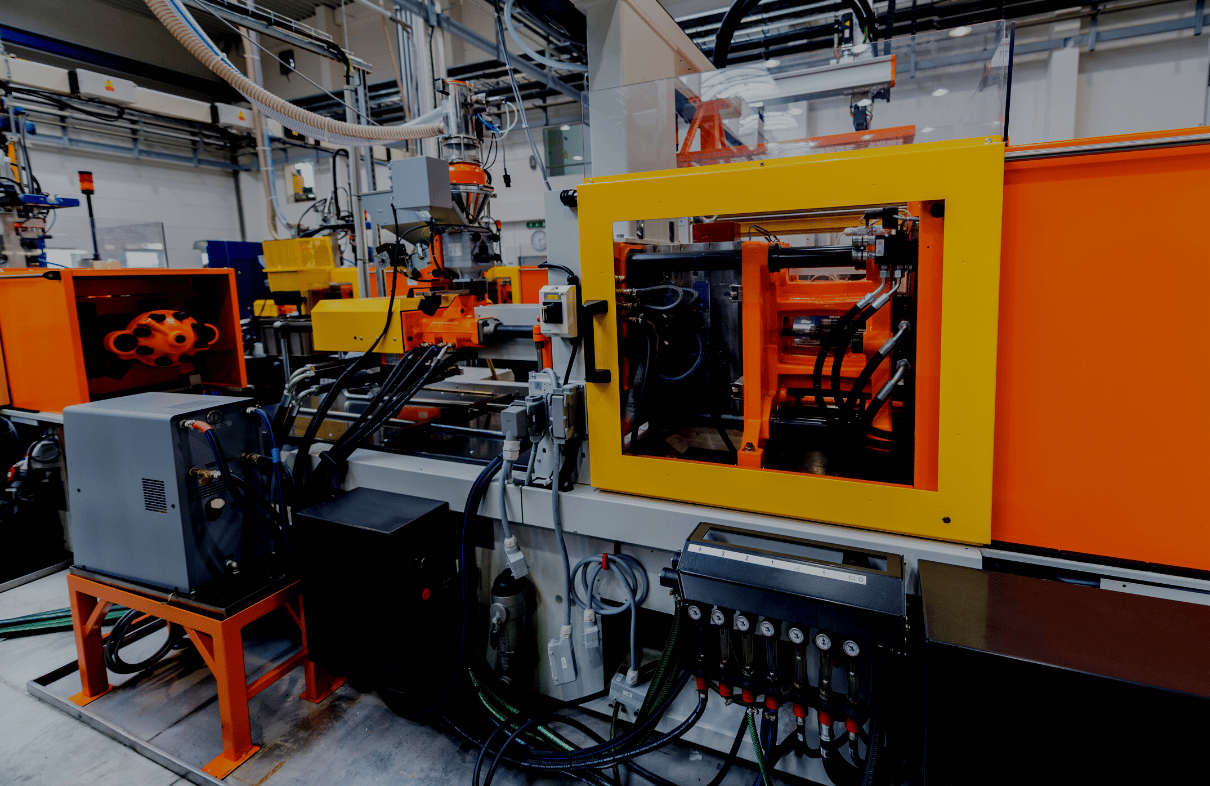

The Types of Equipment Used for the Injection Molding Process

The most common pieces of tooling equipment used for custom injection molded plastic will be an injection ram, a screw-type plunger, an insert molding, a process heating unit, and a material hopper. Injection molded plastic presses are typically rated in tonnage, which indicates the amount of custom plastic part pieces they are capable of producing in a day. The tonnage can vary between 1 ton to over 10,000 tons.

How to Choose the Right Molding Manufacturer

With so many injection molding manufacturers to choose from, it can be difficult to choose the injection molding process that is right for your particular needs. While there are many good injection molding manufacturers to choose from, being good at what they do does not necessarily mean that they will be good at what you need them to do.

The most important thing to look for when choosing an injection molding manufacturer is to see what size presses they have. The key is to find out how many different sizes they’re able to employ in the process, as this will directly translate into them being able to adapt to whatever your needs are. A wider variety of press sizes also means a better selection of injection molding materials and colors, and also minimizes the amount of vendors that you will have to deal with.

Another important aspect to consider when choosing the right injection molding manufacturer is what their ability is to expand their process. If you anticipate your demand for parts suddenly growing, it is vital that your manufacturer be able to quickly and seamlessly be able to grow to accommodate your increased demand.

Injection Molded Plastic Terms

- Backing Plate

- A plate that provides support for the mold cavity block, guide pins, bushings and so forth.

- Cavity

- The space inside a mold into which the material is injected.

- Charge

- The amount of material needed to fill a mold during a single cycle.

- Cooling Channels

- Channel through which a cooling medium flows to control the temperature of the surface of the mold. Cooling channels are located within the body of the mold.

- High Density Polyethylene (HDPE)

- Plastic used to package products with short shelf lives, such as bottles for milk, juice, water and laundry products. Unpigmented HDPE bottles are translucent and have good stiffness.

- Hydraulic Units

- Devices that use the force of fluids to move the mold in the injection molding process.

- Linear Low Density Polyethylene (LLDPE)

- A plastic that is used predominantly in film applications due to its toughness and flexibility. LLDPE is the preferred resin for injection molding because of its superior toughness and is used in items such as grocery bags, garbage bags and landfill liners.

- Mold

- A series of steel plates, which contain cavities into which plastic resin is injected to form a part.

- Monomer

- A relatively simple compound that can react to form a polymer.

- Melt Index

- A test that measures the ability of molten plastic to flow.

- Melting Point (Tm)

- The temperature at which crystalline portions of polymers melt. A material becomes soft and completely amorphous once it reaches the Tm.

- Melt Viscosity

- A term that refers to the measure of resistance to flow. For all materials, the viscosity decreases as the temperature increases.

- Polymer

- A term that means many units. These units are linked together to form chain-like structures that give polymers unique properties.

- Polypropylene (PP)

- A very strong substance that has the lowest density of the plastics used in packaging. PP has a high melting point, making it ideal for hot-fill liquids.

- Polystyrene (PS)

- A very versatile plastic that can be rigid or foamed and has a relatively low melting point. General purpose polystyrene is clear, hard and brittle.

- Resin

- Any of a class of solid or semi-solid organic products of natural or synthetic origin, generally of high molecular weight with no definite melting point. Most resins are polymers.

- Thermoplastics

- Materials that can be melted by heating and then re-solidified by cooling. Blends of thermoplastics can be prepared by melt-mixing.

- Thermosets

- Materials that “cure” to form solids when heated. Unlike thermoplastics, solid thermosets do not melt when heated, so they are very useful for high heat applications.

- Toggle Unit

- Device that uses mechanical links to move the mold during the formation of injection molded plastics.

- Overmolding

- A process that is very similar to the standard injection molding process except for the fact that it combines two materials. The process is actually performed twice, making it a great option for applications where durability and reliability are required.

Diving Deeper – Applications

Injection moulding is popular with any customers looking for parts that are difficult to create by hand. It is also popular with those manufacturers looking to keep their production and tooling costs low. As such, injection molded plastics have countless applications. They are used in a wide range of industries, such as consumer products, household, electronics, automotive manufacturing, aerospace, sports and recreation, and healthcare.

Products Produced

It is possible—even encouraged—to fabricate any sort of plastic material product if a manufacturer can make a plastic mold cavity for it.

For instance, a wide variety of everyday household items are manufactured using plastic injection molding or custom injection molding processes. Examples include plastic containers, gaming cartridges, buckets, and tool handles. In addition, numerous commercial, industrial and medical products can be made from injection moulding. Examples include vehicle bumpers, medical equipment, airplane parts, bottles, bike parts, rubber balls, and enclosures.

History

John Wesley Hyatt and his brother Isaiah invented injection moulding in 1872. Their injection moulding machine model was quite simple, consisting of a plunger that pushed plastic material through a heated barrel into a steel mold cavity, where it could take on its shape. At that time, creating molds was very time-consuming and not particularly complex. Also, manufacturers primarily used a plastic material, cellulose nitrate, which was quite flammable. All in all, injection molding in the 1800s was quite limited. Some of the products that manufacturers made with early injection molding machines included combs, collar stays, and buttons.

In 1903, Theodore Becker and Arthur Eichengrun, two German chemists, invented one of the first synthetic plastic materials, soluble cellulose acetate. This invention offered manufacturers a much safer, much less flammable material option.

In 1919, one of those same chemists, Arthur Eichengrun, patented his own version of the injection molding process, which he designed to work with the first modern injection molding machines.

While injection molded plastic products offered promise, manufacturers had neither a great variety of plastic material nor a large customer base before World War II. WWII created a demand for plastic products for the war effort. This pushed chemists to quickly come out with new synthetic plastic formulas, and engineers to come up with better ways to mold them into products. Heeding the call, in 1946, American James Watson Hendry designed screw injection mold machines. His machine allowed manufacturers to create the parts with much greater precision and far fewer errors. It also allowed them to mix additives, such as pigment, into raw plastic before molding it. Screw injection molding machines are popular manufacturing mechanisms to this day.

After WWII ended, the United States experienced a huge economic boom, and the demand for plastic products, which was virtually non-existent before, exploded. With that, injection molding solidified its place in our world. Today, this manufacturing industry continues to expand. Every year since 1995, the number of available custom plastic products have increased by a rate of approximately 750. In addition, the number of available custom plastic materials has increased over the years. An important change the plastic industry has been making since the late ‘80s and early ‘90s is the shift to sustainable practices. That’s why they have turned away from many plastic materials that cannot be recycled, as well as many tooling procedures that use up a lot of energy.

Materials

Generally speaking, manufacturers carry out the injection molding process with elastomers, thermoplastics, and thermosets. These are large categories under which a wide variety of plastics fall. To learn more these categories and some of the most common plastics that manufacturers use during injection molding, check out the descriptions below.

Elastomers are materials that can change shape more easily than other solids, while upon cooling and hardening, retain their elasticity and original strength. This quality is called viscoelasticity. Elastomers, such as nylon, are popular for their versatility.

Thermoplastics are polymers that manufacturers can render molten without applying too much heat. When they have cooled, thermoplastic injection molded parts harden completely. However, manufacturers can heat them up again to reshape them or fix an error. Thermoplastics also have a high molecular weight. Manufacturers like thermoplastics because they have low tooling and production costs.

Thermosets are polymers that, once processed, cannot be reformed into something new. While they are not reusable, they are extremely durable and work well in high temperature environments.

Polyethylene is a highly impact resistant, ductile, and friction resistant thermoplastic. It also offers good electrical insulation, low permeability, and high chemical resistance. Common varieties include high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Polyethylene is the most widely produced plastic in the world, and it is popular as injection molded packaging, bottles, and containers.

Polypropylene is a low-density, chemical resistant thermoplastic that manufacturers like to use to create packaging. They also use it to produce injection molded items such as car parts, medical devices, and lab equipment. It is very strong and has a very high melting point, so it is perfect for holding hot liquids.

Nylon is a thermoplastic elastomer. Manufacturers have used it since the 1930s. Nylon is durable, wear resistant, chemical resistant, abrasion resistant, friction resistant, and thermally stable. Nylon can be used to make many different injection molded products, such as automotive parts, medical devices (e.g. catheters), footwear, and sporting goods.

Epoxy resins are thermoplastic polymers that offer weather resistance, temperature resistance, corrosion resistance, and strong bonds. Manufacturers use epoxy to injection mold products like bottle caps, plastic cups, utensils and cooking implements, automotive parts, appliances, motor components, insulator parts, generator components, and parts of furniture.

Polystyrene is an inexpensive plastic product with a fairly low melting point. It comes in both foamed and rigid forms. This hard, brittle product works well as protective packaging, disposable silverware, trays, bottles, tumblers, and lids. A large drawback of polystyrene is the fact that it is not recyclable.

Phenolic resins are synthetic thermosetting polymers used to inject mold plastic products like laboratory countertops and pool balls (billiard balls). Phenolic resins are not as popular as they once were, as they’ve been largely supplanted by materials like epoxy and fiberglass.

Process Details

The plastic injection molding process involves a few key steps: plastic melting, plastic injection, shaping, cooling, and releasing.

1. Melting

During this step of the process, manufacturers move plastic from the hopper, where it is held before the process begins, to the heating unit, where it is heated and mixed until molten. In its melted state, manufacturers can add additional chemical agents, such as dye, in order to achieve a certain final appearance and texture of the product.

2. Injection

The next step of the production process is injection. During this step, a screw, also known as an injector, uses mechanical or hydraulic pressure to force the melted plastic into the mold cavity.

3. Shaping

While inside the mold, the molten plastic flows until it takes on the shape of the mold cavity. Then, it cools and hardens. The presence of air bubbles will be harmful to the product. However, most molds are capable of allowing the air bubbles to escape.

4. Cooling

The cooling process—and thus, the overall manufacturing procedure—may be hastened by the use of cooling liquids around the molding chamber that removes heat from the plastic.

5. Releasing

The newly cooled and hardened plastic part is released after the two halves of the injection mold cavity are pulled apart. Sometimes, a set of ejecting pins or rods has to be removed from the mold as well. The removal process can take anywhere from a few seconds to a few minutes.

6. Secondary Processing

Injection molded products do not generally require secondary processing. However, sometimes they do. If, for example, the final product comes away with joining lines or other forms of imperfections, the product may require undergoing a finishing procedure. The amount of finishing required at the end of the production process depends on the quality of the mold cavity and the material used.

Design

Before injection molding a plastic product, manufacturers have a few decisions to make, based on application/product specifications such as required material strength, expected chemical exposure, expected frequency of use, expected temperature exposure, intended product life, customer budget, etc.

The decisions they make based on these specifications include the type of plastic material to use, the product shape and dimensions, mold design, and whether or not they will use custom injection molding. Custom injection molding is a process in which the mold cavity is not a pre-made design but is specifically formed according to the consumer’s requirements. While custom injection molding drives up the costs of the otherwise cost-effective injection molding process, the cost is balanced if your product request volume is quite high.

Variations and Similar Processes

Gas assist injection molding is another variation of plastic molding, which involves the use of an inert gas material, such as nitrogen, to hollow out the mold and assist in filling the mold cavity with molten plastic.

Reaction injection molding is a second injection molding variation. It requires an additional step during which a reaction injection molding machine adds a curing agent to the mold cavity. The curing agent ensures that the product material maintains its shape and strength upon removal from the mold cavity.

Benefits

The plastic injection molding process offers many benefits to both manufacturers and product end users. First, in comparison to other production methods, injection molding is very cost-effective. This is especially true when manufacturers mold in bulk. The more parts that can be made from one mold cavity, the more cost-effective production will be. Along those same lines, a mold cavity for a particular product can be reused multiple times once it has been fabricated, and it can produce the same product with minimal differences. This saves time, money and resources, not to mention it makes injection molding ideal for high production runs.

Another advantage of injection moulding is the fact that the injection molding process involves little to no change in the process, and the plastic parts rarely need additional finishing once removed from the mold cavity. Also, it has low tooling costs. The process also leaves minimal waste, and the small amount of plastic scrap that the process does create can easily be recycled. Since human interference is rarely necessary, the injection mold process has extremely low labor costs and other risk costs. Finally, injection molding is extremely versatile.